C1200 – Checkweigher solution for net weight control in industry

Food and Feed Processing Producers are becoming more concerned with whether each product they produce has the proper net weight in light of recent economic volatility and rising inflation.

Monitoring net weight and output quantity precisely helps to reduce material loss and waste. Furthermore, it aids in database updating and real time management to tightly ensure raw material weight and final product weight are under controlled.

However, finding the right Solutions and Equipment to meet this requirement is not easy.

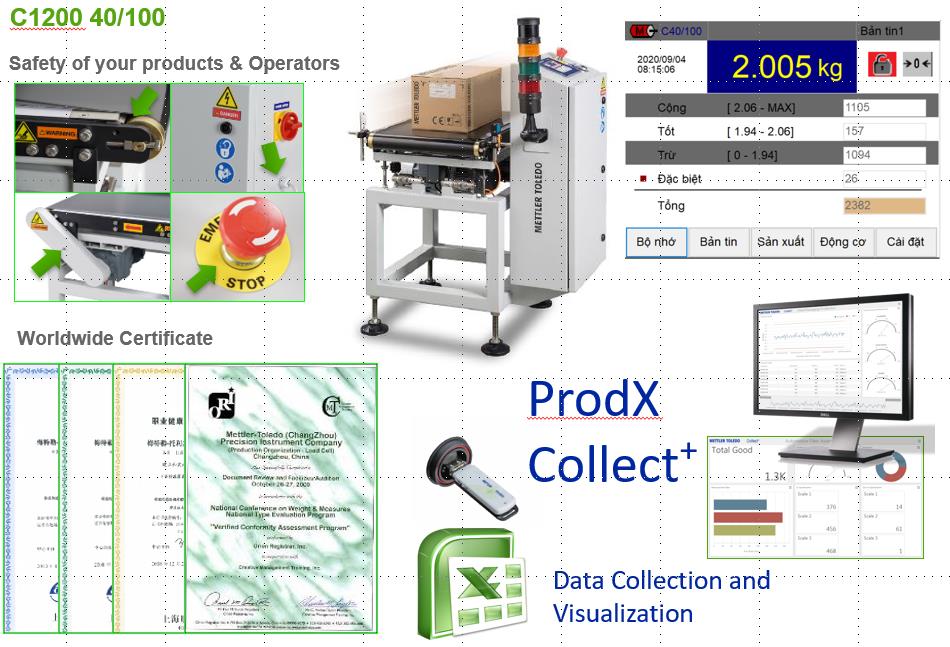

Currently, the METTLER TOLEDO Checkweigher Solution, which is frequently installed at the end of the manufacturing line or in the import and export area, has assisted major companies in monitoring the weight of raw material and finished product, resulting in more precise packaging (automatically send feedback signal to adjust the net weight of the underweight or overweight bags to the proper net weight).

|

|

Besides, Prod X software supports in connection with other METTLER TOLEDO’s equipments, helping to transfer data continuously so businesses can manage and access full data reports at any time.

These completed solution s ha ve been applied in the largest factories in Vietnam, including Wilmar Argo, Suntory PepsiCo, OFI Group, Syngenta, and Checkweigher integration is an essential element of quality control because it:

– Checks 100% of product weights

– Verifies product weight integrity

– Checks and s ort s by appropriate product weight ranges

– Ensure the standards of legal metrology are met.

Find out more about the Checkweigher METTLER TOLEDO via Link or contact us at

Company: Mettler Toledo Viet Nam

Address: G Floor, SCS Building, Plot T2-4, D1 Street, Hi-tech Park, Tan Phu Ward, Thu Duc City, Ho Chi Minh City

Booth: A5-A6

Hotline: 028 7309 0789

Website: www.mt.com